THREE O R��D/Laboratory

�@�@�J���E�������@�X���[�I�[�@�@

�@�@�@�@�@�@�@�@�@

1.Development and practtttical application of Nanocrystallite Metals and

their applied products.

2.Elucidation of mechanismes of Nanocrystalline Metals and their appllied

products.

THREE O R��D/Laboratory

�J���E�������@�X���[�I�[

1958-229 Nakano,Midori-Ku,

Sagamihara,Kanagawa 252-0157 Japan

�@TEL:+81-42-780-7076

�@FAX:+81-42-780-7076

�@e-mail:ogasa.three-o@ka2.

�@�@ so-net.ne.jp��252-0157

�_�ސ쌧���͌��s�撆��1958-229

TEL 042-780-7076

FAX 042-780-7076

e-mail:ogasa.three-o@ka2.

�@�@�@so-net.ne.jp

ED(HFSilver Bonding �@�@

ED(HFSilver Bonding �@�@Wire�̗p)�@2009�N���R��

���菤����@�Ɋւ���L�q

Three O Co., Ltd. has developed alloys (Au, Ag, Al, Cu, Pt, etc.) that exhibit oundbreaking functional properties. .

Metal application products made from this new alloy have been found to exhibit groundbreaking high performance properties.

In the only high-purity metals with a purity of 99.99 or more that are not normally used, the groundbreaking properties decrease and approach normal properties.

It has been found that groundbreaking properties can be obtained with commonly used alloys (Au, Ag, Al, Cu, Pt).

Development has initially aimed to develop hard alloys, and then high-functional properties. .

All of these have been achieved by changing the same manufacturing method and the same composition method.

Crystallites in metal products were nano-sized.

It was a nanocrystalline metal.

It was found to be an ultra-fine crystallite metal with high functional properties.

Three O Co., Ltd. has been manufacturing new alloys and their application products

Three O Co., Ltd will be changed to Three O R&D/Laboratory and manufacturing will be carried out as a project

On December 1, 2024, I established Three O R&D/Laboratory.

As for me, I will continue to develop products and manufacturing methods at Three O R&D/Laboratory

I believe that in production, we need to listen to the opinions of many people, find the most optimal method without waste, and put it into practice as quickly as possible.

This new alloy and its application products show unprecedented, revolutionary high performance and high quality characteristics, and are notable for their energy saving and Decarbonization. .

It eliminates waste, can be manufactured efficiently, changes little over time, and is non-toxic.

Applicable alloys include Au, Ag, Al, Cu, Pt, etc., and are not limited to composition.

Applicable alloys and their application products are infinite, and are not limited except by purity.

This is the metal alloy of the future that we are looking for.

Three O Co., Ltd. is small, so we cannot manufacture it.

I have established a new research and development laboratory, THREE O, to focus on the following.

1.Development and practtttical application of Nanocrystallite Metals and their appllied products.

2.Elucidation of mechanismes of Nanocrystalline Metals and their appllied products.

I discovered that it is possible to obtain metal alloys with ultrafine grain size of ultrafine crystallite (1nm to 100nm) nano size, and established a manufacturing method.

I named this new alloy Fine crystallite High Function Metal Alloys.

The characteristic of this new technology is that we discovered that revolutionary functional properties can be obtained by miniaturizing the grain size of metal alloys to nano size (1995).

I. have applied for international patents (USA, Europe, Australia, China, etc.). Obtained.

2. Features of the new method.

2-1 Applicable alloy types

�@Ag alloy, Au alloy, Al alloy, Cu alloy, Pt alloy, etc.

2-2 Purity of applicable alloys

The revolutionary properties are shown up to 99.99% purity.

At purities of 99.99% or more, the revolutionary properties approach normal property values.

The new method is not limited to one alloy, one composition, one purity, etc., as in the conventional method.

It is characterized by its applicability to the above metal alloy compositions.

Since it is not limited to the composition, the range of application is wide. In contrast to the conventional method.

3. Features of properties obtained by the new method

3-1 Even if a property is improved, other properties are hardly deteriorated.

For example, even if the tensile strength is improved, the conductivity rate is hardly deteriorated.

3-2 A wide range of properties are improved and enhanced.

The properties that are improved and enhanced are shown below.

�@Improvement of various performance characteristics.

�AImprovement of various quality characteristics.

�BImprovement of cost performance (decarbonization effect, energy saving).

�ESpeeding up of processing�EElimination of softening heat treatment process�@

�EElimination of precious metals for plating and elimination of plating process

�EElimination of hydrogen gas and elimination of process using that gas

�EReduction of alloy recycling process

�EElimination of inert gas and elimination of process using that gas

�EReduction of expensive factory equipment

�EReduction of elemental analysis process

�EPrevention of dust generation in wire drawing process

�EImprovement of sound by improving Young's modulus of wind instruments and percussion instruments.

�DDecarbonization.

�EEnergy saving.

�FImprovement of manufacturing yield.

�GNo Aging.

�HPollution-free.

�I Improved Young's modulus

We have been manufacturing and evaluating application products using new metal alloys. .

The characteristics of application products obtained from the new alloys are shown above.

Simple is the best

Practical results 1.

Manufacturing process of the new silver alloy

I have been developing new alloys and their applied products. The crystallite size of the new alloy is on the nanometer level.

The new alloy exhibits breakthrough high-Function properties. Applications made from this alloy exhibit innovative high-value-added properties.

I call this new alloy "Fine Crystallite High-Function Metal Alloys."

This time, I will explain the characteristics of the new alloy manufacturing process.

Table 1 shows the characteristics of the manufacturing process of Fine Crystallite High Function SilverAg99.7% and its applied products. For comparison, we have shown the characteristics of the manufacturing process of conventional silver alloys and their applied products.

F. C. H. F. Metals Alloy's manufacturing process shows that waste is eliminated.

The advantage of being able to process and store products in the atmosphere is significant.

1. Alloy

Fine crystallite High Function SilverAg99.7%

2. Alloy purity

Ag99.7%

3. Applied products.

3-1 Even if you increase a target's characteristics, other characteristics hardly decrease.

For example, even if the tensile strength is increased, the electrical conductivity will hardly decrease.

3-2 Improving added value

(1) Improvement of various performance characteristics

(2) Improvement of various quality characteristics

(3) Improving cost performance (higher quality/lower cost)

1. Process deletion

�EAnnealing/heat treatment process

�EPrecious metal Pd plating process

�EUse of hydrogen gas

�EUses argon gas

�ERecycle melting

�EAlloy recycling analysis

2. Reduction of wire drawing processing time

3. Prevention of dust generation

4. Decarbonization

5. Energy saving

6. Improved manufacturing yield.

7. No Aging

8. No pollution

9. Detoxification

10.Improvement of Young's modulus

11, Application product example (Thickness 0.6mm board)

Crystallite diameter: 20nm, Vickus hardness: 132

It has been found that applied products obtained from innovative high-performance

alloys exhibit innovative value-added properties.

Furthermore, I were able to efficiently manufacture metal products without

waste.

Simple is the best.

It was also found that the effects of decarbonization, energy saving, and

cost performance are significant.

Although there is a lot of know-how to put high-performance alloys and

their applied products into practical use, we have found that this can

be done easily and inexpensively.

There are a wide variety of technical fields where it can be applied.

There are many types of applicable alloys, including gold, silver, copper,

aluminum, and platinum.

Furthermore, the application fields are expanding to include electronic

parts, automobile parts, aircraft parts, musical instruments, daily goods,

jewelry, etc.

In the future, we will continue to elucidate the mechanisms behind the

groundbreaking high-performance properties and groundbreaking value-added

properties.

I will observe sample products whose characteristics have been demonstrated

and investigate and elucidate them.

This technology is nanotechnology and high-tech.

Practical results �Q

Characteristics of ��25��m wire for electronic parts and everyday items using the new silver alloy

I have discovered that it is possible

to obtain metal alloys with nano-sized ultrafine particles, and have

established a manufacturing method.

This alloy exhibits innovative high-performance properties, and its applied

products exhibit innovative high-value-added properties.

I created ultra-fine wires using a new alloy, Fine crystallite High Function

Silver Alloy, and evaluated its properties. The results are shown below.

1. Alloys and their purity

silver alloy. Ag purity: �@99.7%, �A99.85%, �B99.97%

3. Characteristics of applied products.

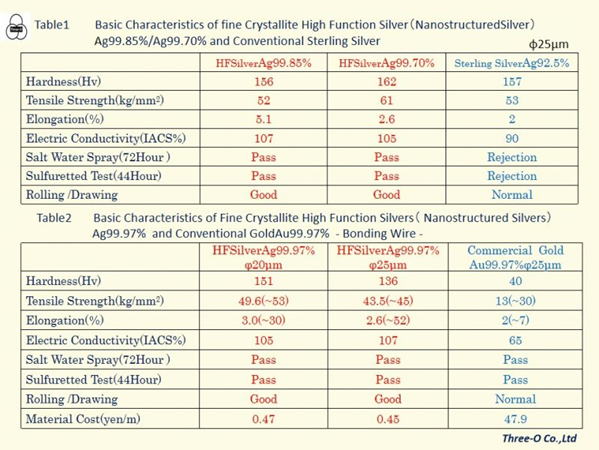

Results are shown in Tables 1 and 2.

Table 1 shows the characteristics of applied products of Ag99.7% and Ag99.85,

and of applied products of general commercial silver product Sterling Silver

Ag92.5%.

F. c. H. F. Silver's conductivity is almost 20% higher.

Sterling Silver failed salt spray and sulfidation tests.

F. c. H. F. Unprecedented revolutionary characteristics of Silver applied

products

1. Passed sulfurization, oxidation, and discoloration tests.

1-1. Inert gas is no longer required during processes such as processing, heat

treatment, storage, cooling, and evaluation.

Inert gas and equipment have been removed.

I have realized processing in the atmosphere.

1-2. Re-dissolution and re-analysis due to discoloration are no longer

required. These steps have been deleted.

1-3. A protective film is no longer required, and the Pd (high precious metal)

plating film and its equipment have been removed.

1-4. By removing the plating film, we have achieved non-toxicity and non-pollution.

2. High processing properties.

The annealing process has been removed.

3. High strength properties

Added copper 7.5% has been removed.

Characteristics are stable and re-melting adjustment is no longer necessary.

Removed the remelting step.

4. High aging properties.

Manufacturing and storage have become stable. Achieved high reliability.

Table 2 shows the characteristics of Fine crystallite High Function Ag99.97%

and Conventional Gold Au99.97% bonding wire.

Silver wire has the characteristics of gold wire.

The price is 1/80 of gold wire (Silver/Gold: 2,295,00$/1,917,50$)

This time, we were able to efficiently manufacture a silver alloy product that

exhibits groundbreaking properties without wasting any waste.

Simple is best.

It has become clear that the effects of decarbonization, energy savings, and

cost performance are also significant.

I will advance practical application and elucidation of the mechanism for the

benefit of the future Earth and humanity.

There are many applicable metal alloys, and their composition fields are also

expanding.

Moreover, the fields of its applied products are wide-ranging.

This technology is advanced technology and high-tech with nanotechnology.

Many people can play an active role.

You will be provided with a high value-added workplace.

I need the help and investment of many people.

Practical results �R�B

Applications and characteristics of the new

silver alloy

I have been developing new alloys and their

application products. I have found a way to manufacture efficiently and without

waste.

This alloy exhibits breakthrough high-Function properties. Application

products of this alloy show epoch-making high value-added characteristics.

I call this new alloy Fine Crystallite High-Function Metal Alloys.

This time, we used Fine crystallite High Function Silver Ag99.7%

to produce an applied product, so its characteristics are shown below.

1. Types of new alloys

Fine crystallite High Function Silver Ag99.7%

2. Alloy purity

Ag99.7%

3. Applied Products.

3-1 Even if you increase the target's traits, other traits hardly

decrease.

For example, increasing the tensile strength hardly reduces the electrical

conductivity.

3-2 Improvement of added value

(1) Higher performance.

(2) Higher quality.

(3) Improved cost performance (higher quality/lower cost)

�EReduction of production process processing time

�ERemoval of the annealing heat treatment process

�EElimination of precious metal plating protective film. Removal of

plating process

- Eliminate the use of hydrogen gas. Removal of processes using hydrogen

gas

�EElimination of the alloy recycling analysis process

�EElimination of alloy recycling melting process

�ERemoval and reduction of processes using inert gas

�ERemoval of expensive factory equipment

�EPrevention of dust generation in the wire drawing process

4. Decarbonization

5. Energy saving

6. Improved manufacturing yield.

7. Improved aging effect

8. Pollution-free

9. detoxification

10. Improved Young's modulus

If the Young's modulus is high and the recovery rate is high (if

the rigidity is high), it will repeat fine vibrations like a thin string

(light specific gravity) in order to return to its original state quickly

so as not to be defeated by external impacts. A high-pitched sound comes

out.

Improves the sound of wind and percussion instruments.

Table 1 shows the characteristics of Fine crystallite High Function

Silver Alloys 99.7% applied products.

For reference, the characteristics of the applied product of F.C.H.F.

Silver99.85% and the applied product of Conventional Sterling Silver Ag92.5%

are shown.

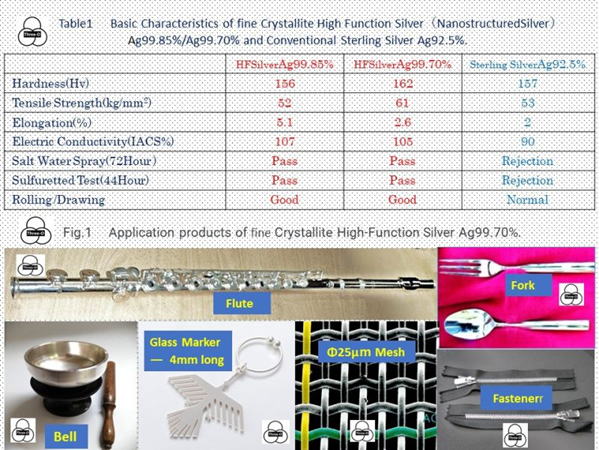

Fig.2 shows a sample application product.

We were able to manufacture metal products efficiently with little

waste.

I am convinced that I can contribute to society.

Simple is the best.

It was found that the effects of decarbonization, energy saving,

cost performance, etc. are also great.

I will continue to develop this. I would like to proceed with the

practical application and elucidation of the mechanism.

There are a wide variety of technical fields that can be applied.

This technology is nanotechnology, high-tech, and expensive to develop.

It requires a lot of manpower. We need a lot of funds.

I need the understanding of many.

Needs support and investment.

Practical results �S�D

Characteristics of bonding wire using the

new silver alloy

I have been developing new alloys and their application products. We have

found a way to manufacture efficiently and without waste.

This alloy exhibits breakthrough high-function properties. It was found

that the applied products of this alloy have epoch-making high value-added

characteristics.

I discovered that by making the crystal grain size of metal alloys nano-sized.

I call this new alloy Fine Crystallite High-Function Metal Alloy.

The advantages of applying Fine crystallite High Function Silver Ag99.97%

to conventional bonding wires (bonding wires other than gold) are shown

below.

1. high performance

High tensile strength, electrical conductivity, etc. It has good elongation

and good workability.

2. high quality

Passed the sulfurization test and chloride test. Can be worked and stored

in air.

3. Removal of plating factory

Removal of high-tech thin film manufacturing equipment.

Removal of pollution control equipment.

Removal of detoxification equipment.

Eliminates expensive elemental Pd

Abolished the use of electricity, water, inert gas, etc.

4. Eliminated the use of inert gases in clean rooms

5. Abolition of use of hydrogen gas in the bonding process

4. Eliminated the use of inert gas during sample storage.

5. Removal of annealing heat treatment process

6. Abolished the use of inert gas in the aging heat treatment process

7. Elimination of re-analysis process for recycled products

8. Elimination of re-melting process for recycled products

9. Improved manufacturing yield

10. Massive reduction in production time by removing and simplifying various

processes

11. Improving the sound of wind/percussion instruments by increasing Young's

modulus

We were able to manufacture metal products efficiently with little waste.

Simple is the best.

It was found that the effects of decarbonization, energy saving, cost performance,

etc. are large.

I will continue to develop this. We will proceed with practical application

and elucidation of themechanism.

There are a wide variety of technical fields that can be applied.

This technology is nanotechnology, high-tech, and expensive.

It requires a lot of manpower. need a lot of money.

I need the understanding of many people.

Needs support and investment.

Table 1 shows the properties of microcrystalline high performance silver

bonding wire compared to gold bonding wire.

The processing method of silver wire is the same as that of gold wire in

atmospheric processing. Currently, the price of silver is about 1/80 of

the price of gold.

Fig. 1 shows the results of a high-acceleration temperature and humidity

stress test (reliability test results) compared with gold bonding wires.

It was found that the results of the high-acceleration temperature and

humidity stress test were almost the same as those of the gold wire.

�@�@�@�@�@�@

�@�@�@�@�J���E�������@�X���[�I�[

�@�@�@�@THREE O R��D/Laboratory

1.�i�m�T�C�Y�����q�����Ƃ��̉��p���i�̊J���Ǝ��p���B

2.�i�m�T�C�Y�����q�����Ɖ��p���i�̃��J�j�Y���̉��B

�@�J���E������ �X���[�I�[(ThreeO R��D Laboratury�j��ݗ��B

�@

�@������ЃX���[�I�[�ł́A����I�ȍ��@�\���������������iAu,Ag,Al,Cu,Pt���j�J�����܂����B

�@���̐V�������瓾 ����������p���i�́A����I�ȍ����\�����������������Ƃ�������܂����B

�@�ʏ�g���Ȃ��A�B��A���x99.99�ȏ�̍����x�����ł́A����I�����͓����ɂ����Ȃ�܂��B�B

�@�ʏ�g�p���Ă��鍇���iAu,Ag,Al,Cu,Pt�j�j�ł́A����I�����������邱�Ƃ�������܂����B�B

�@�J���́A�ŏ��d��������ڕW�ɁA���ɍ��@�\������ڕW�ɐi�߂Ă��܂����B

�@������A���ꐻ�������Ɠ���g��������ω������āA�ڕW��B�����Ă��܂����B

�@�J�������������i�̌����q�́A�i�m�T�C�Y�ł����B

�@�i�m�����q�����ł����B

�@���@�\�������������������q�����ł��邱�Ƃ�������܂����B

�@������ЃX���[�I�[�iThree O Co.,Ltd�j�ł́A�V�����Ƃ��̉��p���i���J�����A�ꕔ�������Ă��܂���.

�@������ЃX���[�I�[�iThree O Co., Ltd�j�́A�J���E�������X���[�I�[�iThree O R��D/Laboratory�j�ɕύX���܂��@�����̓v���W�F�N�g�Ői�߂邱�ƂɂȂ�܂��B

�@2024�N12��1���ɁA�J���E�������X���[�I�[�iThree O R��D/Laboratory)��ݗ����܂����B

�@�J���E�������X���[�I�[�iThree O R��D/Laboratory)�ł́A���i�J���Ɛ������@�̊J�����p�����āA�i�߂܂��B

�@���Y�́A�����̕��X���l�������������āA���ʂ̂Ȃ��A�œK�ȕ��@�����o�����A���}�Ȏ��s�����߂��Ă��܂��B

�@���̐V�����Ƃ��̉��p���i�́A�]���ɂȂ�����I�����\�ƍ��i���̓����������A�ȃG�l�ƒY�f���ʂ������ł��B�B

�@���ʂ��Ȃ��A�����I�ɐ���ł��A�o���ω������Ȃ��A���łł��B

�@�K�p���������́AAu,Ag,Al,Cu,Pt���ł���A�g���Ɍ��肳��܂���B

�@�K�p�����Ƃ��̉��p���i�́A�����ł���A���x�ȊO�Ɍ��肳��܂���B

�@��X�����߂関���̋��������Ƃ��āA���҂ł��܂��B�B

�@�V�����̎�ނ͖�����ł���A������ЃX���[�I�[�iThree O Co., Ltd�j�ł͂��̐��Y�ɂ͑Ή��ł��܂���B

�@�V���ɊJ���E�������X���[�I�[�iTHREE O R��D/Laboratory�j�ݗ����āA���L���ڂɐ�O���邱�Ƃ̂��܂����B

�@�P.�i�m�T�C�Y�����q�����Ƃ��̉��p���i�̊J���Ǝ��p���B

�@�Q.�i�m�T�C�Y�����q�����Ƃ��̉��p���i�̃��J�j�Y���̉𖾁B

���́A���������q�i1nm�`100nm�j�i�m�T�C�Y�̒����׃O�����T�C�Y�̋��������������邱�Ƃ����A�������@���m�����܂����B

���̐V������Fine crystallite High Function Metal Alloys�Ƃ��܂����B

�V�Z�p�̓����́A���������̃O�����T�C�Y���i�m�T�C�Y(1995)�ɔ������邱�ƂŁA����I�ȋ@�\�����������邱�Ƃ����o���܂����B

���ۓ����i�č��A���[���b�p�A�I�[�X�g�������A�������j���o��B�擾�擾���܂����B

2�A�V���@�̓����B

2-1 �K�p�����̎��

�@Ag�����AAu�����AAl�����ACu�����APt������

2-2 �K�p�����̏��x

�@����I�����́A�����x99.99���܂Ŏ����܂��B

�@���x99.99���ȏ�ɂȂ�ƁA����I�����͒ʏ�̓����l�ɐڋ߂��܂��B�B

�V���@�́A�]�����@�̗l�ɂP�����A�P�g���A1���x���Ɍ��肳��܂���B

��L�̋��������g���ɓK�p�ł��邱�Ƃ������ł��B

�g���Ɍ��肳��Ȃ��̂ŁA�K�p�͈͂��L�͈͂ɂȂ��Ă��܂��B�]�����@�Ƃ͑ΏۓI�ł��B

3�A�V���@�œ���������̓���

3-1 ���������コ���Ă��A���̓������w�ǒቺ���܂���B

�Ⴆ�A�������x�����コ���Ă��A���d�����͖w�ǒቺ���܂���B

3-2 �L�͈͂̓��������P����A���サ�܂��B

���L�ɉ��P�A���シ������������܂��B

�@�@�e�퐫�\�����̌���B

�@�A�e��i�������̌���B

�@�B�R�X�g�p�t�H�[�}���X�̌���i�E�Y�f���ʁA�ȃG�l�j�B

�@�@�E���H�̃X�s�[�h�A�b�v�E��M�����H���̍폜�@

�@�@�E�t���p�M�����̍폜�Ƃ��̓t���H���̍폜

�@�@�E���f�K�X�̍폜�Ƃ��̃K�X�g�p�H���̍폜

�@�@�E�������T�C�N���H���̍팸

�@�@�E�s�����K�X�̍폜�Ƃ��̃K�X�g�p�H���̍폜

�@�@�E�H�ꍂ���ݔ��̍팸

�@�@�E���f���͍H���̍팸

�@�@�E�L���H���̔��o�h�~

�@�@�E�NJy��A�Ŋy��̃����O���̌���ɂ�鉹�̉��P�B

�@�D�E�Y�f���B

�@�E�ȃG�l�B

�@�F���������܂�̌���B�@

�@�G�V���h�~�B�B

�@�H�����Q���B

�@�I�����O���̌���

�V�������������ŁA���̉��p���i�����A�]�����Ă��܂����B�B

�V�����œ����鉞�p���i�̓������A��L�Ɏ����܂����B

Simple is the best.

���n��P�D

���������q�⍇���̐����v���Z�X

���́A�V�K�����Ƃ��̉��p���i�̊J�������Ă��܂����B�V�����̌����q�T�C�Y�̓i�m���[�^���x���ł��B

�V�����́A����I�ȍ��@�\�����������܂��B���̍������琻�삷�鉞�p���i�́A����I�ȍ��t�����l�����������܂��B

���͂��̐V�������uFine Crystallite High-Function Metal Alloys�v�ƌĂ�ł��܂��B

����́A�V�����̐����H���̓���������������܂��B

Table�P�ɂ́AFine Crystallite High Function SilverAg99.7%�̐����H���Ƃ��̉��p�i�̐����H���̓����������܂����B��r�ׂ̈ɁA�]���̋⍇���Ƃ��̉��p���i�̐����H���̓����������܂����E

F. C. H. F. Metals Alloy�̐����H���ł́A���ʂ���������Ă��邱�Ƃ�������܂��B

���i�̉��H�ƕۊǂ���C���ōs�����Ƃ̏o������ʂ͑傫���B

1. ����

Fine crystallite High Function SilverAg99.7%

2. �������x

Ag99.7%

�R ���p���i�B

3-1 �Ώۂ̓����𑝂₵�Ă��A���̓����͂قƂ�nj���Ȃ�

�Ⴆ�A�������x���グ�Ă��A�d�C�`�����͂قƂ�ǒቺ���܂���B

3-2 �t�����l�̌���

(1)�e�퐫�\�����̌���

(2)�e��i�������̌�

(3)�R�X�g�p�t�H�[�}���X�̌���(���i�����E��R�X�g��)

�P.�H���폜

�E�ē݁E�M�����H��

�E�M����Pd�߂����H��

�E���f�K�X�̎g�p

�E�A���S���K�X�g�p

�E���T�C�N���n��

�E�������T�C�N������

2. �L�����H���Ԃ̒Z�k

3. ���o�����h�~

4. �E�Y�f��

5. �ȃG�l

6. ���������܂�̌���B

7. �V������

8. �����Q��

9. ���

10.�����O���̌���

11,���p���i��iThickness 0.6�����j

�����q�a�F20nm�A�r�b�J�X�d�x�F132

����I���@�\�������瓾���鉞�p���i�͉���I�t�����l�������������Ƃ�������܂����B

�X�ɁA�������i�ʂȂ������I�ɐ������邱�Ƃ��ł��܂����B

�V���v���E�C�Y�E�U�E�x�X�g�B

�E�Y�f���A�ȃG�l�A�R�X�g�p�t�H�[�}���X�Ȃǂ̌��ʂ��傫�����Ƃ�������܂����B

���@�\�����Ƃ��̉��p���i�̎��p���ɂ́A�m�E�n�E������܂����A�e�ՂɁA�����Ɏ����ł��邱�Ƃ��킩��܂����B

���p�ł���Z�p����͑���ɂ킽��܂��B

�K�p�����̎�ނ́A���A��A���A�A���~�A�v���`�i�������Ȃ��Ă��܂��B

�X�ɁA�K�p������d�q���i�A�����ԕ��i�A�q�i�A�y��A����i�A�W���G���[���L���Ȃ��Ă��܂��B

����́A����I���@�\�����Ɖ���I�t�����l�����́A���J�j�Y���̉𖾂����Ă܂���܂��B

�����������Ă����T���v�����i���ϑ����āA�����𖾂��Ă܂���܂��B

���̋Z�p�̓i�m�e�N�m���W�[�ł���A�n�C�e�N�ł��B

�B

�B���{��Q�D

���������q�⍇���d�q���i�p�Ɠ���i�̃�25��m���C���[����

Fine crystallite High Function Silver Alloy�ɂ��Đ���E�]�����ʂ����L�Ɏ����܂��B

�P. �������x

����g���BAg���x�F�@99.7���A�A99.85���A�B99.97��

�Q. ���p���i�̓����B

������r���ʂ�\�P�ƕ\�Q�Ɏ����܂��B

�\1��Ag99.7%��Ag99.85�̉��p���i�A����ш�ʎs�̋�iSterling Silver Ag92.5%�̉��p���i�̓����������܂��B

Sterling Silver�́A���������Ɨ����e�X�g���N�����[���Ă��܂���B

F. c. H. F. Silver���p���i�̏]���ɂȂ�����I����

�@�@�P�D�����A�_���A�ϐF�e�X�g���N�����[�B

�@�@�@�@1-1.���H�A�M�����A�ۑ��A��p�A�]�����H���ŕs�����K�X���s�v�ɂȂ�B

�@�@�@�@�@�s�����K�X�Ɛ����ݔ����폜���܂����B

�@�@�@�@�@��C�����H���������܂����B

�@�@�@�@1-2.�Đ��ׂ̗̈n���ƕ��͂��s�v�ƂȂ�A���̍H�����폜���܂����B

�@�@�@�@1-3.�ی얌���s�v�ɂȂ�APd(�����M����)���b�L���Ƃ��̐ݔ����폜���܂����B

�@�@2. ���H�����悢

�@�@�@�@�@�ēݍH�����폜���܂����B

�@�@3. ����ō����x�����������܂���

�@�@�@�@�@�Y����7.5%���폜���܂����B

�@�@�@�@�@�������肵�A�ėn�����s�v�ɂȂ�A�ėn���H�����폜���܂����B

�@�@4. �����G�C�W���O�����B

�@�@�@�@�@�����ƕۊǂ����肵�A���M�����܂����B

�\2��Fine crystallite High Function Ag99.97%�K�p�i�̃{���f�B���O���C���[�̓����������܂��B

�@�@��r�̂���Commercial Gold Au99.97���̓����������܂����B

�@�@��C���[�ŁA�����C���[�̓����������Ă��܂��B

�@�@�������x�A�L�сA���d���͋����C���[��荂���Ȃ��Ă��܂�

�@�@���d����45�������Ȃ��Ă��܂��B

�@�@���i��1/80

�@�@�ޗ�������1/80( 2,289,20��/1,918,40��)�B2023�N9��9�����݁B

����́A����I�����������⍇�����i���A���ʂȂ������悭�������邱�Ƃ��ł��܂����B

Simple is the best.�B

�E�Y�f���A�ȃG�l�A�R�X�g�p�t�H�[�}���X�Ȃǂ̌��ʂ��傫�����Ƃ����炩�ɂȂ�܂����B

�l��s���A���G/�����ԍH���A����/���Q�ޗ��̏������N�����[�ł��邱�Ƃ�������܂����B

�����̒n���Ɛl�ނׂ̈ɁA���p���ƃ��J�j�Y���̉𖾂�i�߂����Ǝv���܂��B

�K�p���������͍L���A���̑g��������L���Ȃ��Ă��܂��B

�X�ɁA���̉��p���i�̕���͑����ɂ킽��܂��B

���̋Z�p�́A��[�Z�p�ł���A�i�m�e�N�m���W�[�Ńn�C�e�N�ł��B�����̐l������ł��܂��B

�B

���{�� 3�D

���������q�⍇���̉��p���i�Ƃ��̓���

����A���������@�\��Ag99.7%���g�p���ĉ��p���i���쐻�����̂ŁA���̓������ȉ��Ɏ����܂��B

1. �V�����̎��

�������q���@�\��Ag99.7%

2. �������x

��99.7%

3. ���p���i�B

3-1 �Ώۂ̓������グ�Ă����̓����͂قƂ�lj�����܂���B

�Ⴆ�A�������x�����߂Ă��A���d���͂قƂ�ǒቺ���܂���B

3-2 �t�����l�̌���

(1) ��荂���p�t�H�[�}���X�B

(2) ��荂���i���B

(3) �R�X�g�p�t�H�[�}���X�̌���i���i���E��R�X�g�j

�E���Y�H���̏������Ԃ̒Z�k

�E�ēݔM�����H���̔p�~

�E�M�������b�L�ی얌�̏����B ���b�L�����H��

- ���f�K�X�̎g�p��p�~���܂��B ���f�K�X���g�p����H���̔p�~

�E�������T�C�N�����͍H���̔p�~

�E�������T�C�N���n���H���̔p�~

�E�s�����K�X���g�p����H���̔p�~�E�팸

�E�����ȍH��ݔ��̓P��

�E�L���H���ɂ����锭�o�h�~

4. �E�Y�f��

5. �ȃG�l

6. ���������܂�̌���B

7. �o���ω��̉��P

8. �����Q��

9. ���ʼn�

10. �����O���̌���

�����O���������A�������������i�����������j�ꍇ�́A�ׂ����i��d���y���j�̂悤�ɍׂ����U�����J��Ԃ��A�Ռ��ɕ����Ȃ��悤�ɑ������̏�Ԃɖ߂낤�Ƃ��܂��B

�O������̉e���B �b������(high-pitched sound)���o�܂��B

�ǑŊy��̉������P���܂��B

�\1�ɔ��������@�\�⍇��99.7%�K�p�i�̓����������܂��B

�Q�l�܂łɁAF.C.H.F.�̉��p���i�̓����������܂��B Silver99.85%�Ə]���̏���Ag92.5%�̉��p�i�������܂��B

�}2�ɉ��p���i��������܂��B

�������i�ʂȂ������悭�������邱�Ƃ��ł��܂����B

���͎Љ�ɍv���ł���Ɗm�M���Ă��܂��B

Simple is the best.

�E�Y�f���A�ȃG�l�A�R�X�g�p�t�H�[�}���X�Ȃǂ̌��ʂ��傫�����Ƃ�������܂����B

�l��s���A���G/�����ԍH���A����/���Q�ޗ��̏������N�����[�ł��邱�Ƃ�������܂����B

���́A���p���ƃ��J�j�Y���̉𖾂�i�߂Ă��������ƍl���Ă��܂��B

�K�p�ł���Z�p����͑���ɂ킽��܂��B

���{��4�D

���������q�⍇���̃{���ŃC���O���C���[����

Fine crystallite High Function Silver Ag99.97%���A�]���̃{���f�B���O���C���[�i���ȊO�̃{���f�B���O���C���[�j�ɓK�p�����ꍇ�́A�����b�g�ɂ��ĉ��L�Ɏ����܂����B

�P�D�����\

�@�������x�A�d�������������B�L�т��L��A���H�����ǍD�ł��B

�Q�D���i��

�@���������E���������ɍ��i�B ��C���ō�Ƃƕۊǂ��ł�B

�R�D���b�L�H��̓P��

�@�n�C�e�N�����������u�̓P���B

�@���Q�h�~�ݔ��̓P���B

�@�ŏ����ݔ��̓P���B

�@�����Ȍ��f�� Pd ��r��

�@�d�C�A���A�s�����K�X���̎g�p��p�~�B

�S�D�N���[�����[���ɂ�����s�����K�X�̎g�p�p�~

�T�D�ڍ��H���ɂ����鐅�f�K�X�̎g�p�p�~

�S�D�T���v���ۊǎ��̕s�����K�X�̎g�p��p�~�B

�T�D�A�j�[���M�����H���̓P��

�U�D�����M�����H���̕s�����K�X�g�p��p�~

�V�D���T�C�N���i�̍ĕ��͍H���̔p�~

�W�D���T�C�N���i�̍ėn���H���̔p�~

�X�D���������܂�̌���

�P�O�D���H���̓P���ƃV���v������鐧�쎞�Ԃ̑�K�͒Z�k

�P�P�D�����O������ɂ��NJy��/�Ŋy��̉��̉��P

���ʂ����Ȃ��A�����悭�������i���ł��܂����B

Simple is the Best�ł��B

�E�Y�f���A�ȃG�l�A�R�X�g�p�t�H�[�}���X���̌��ʂ��傫�����Ƃ�������܂����B

���́A��������̊J���B���p���A���J�j�Y���̉𖾂�i�߂Ă܂���܂��B

���p�ł���Z�p����͑���ɂ킽��܂��B

���̋Z�p�̓i�m�e�N�m���W�[�Ńn�C�e�N�ł���A���z�̔�p��v���܂��B

�����̐l�肪�K�v�ł��B �����̎������K�v�Ƃ��Ă��܂��B

�����̐l�̗������K�v�ł��B

�\ 1 �ɁA���{���f�B���O ���C���Ɣ�r���������������\��{���f�B���O ���C���̓����������܂��B

����̉��H���@�́A��C�����H�ŋ����Ɠ����ł��B���݁A��̉��i�͋��̉��i�̖�P/80�B

�}1�ɋ��{���f�B���O���C���[�Ɣ�r���������������x�X�g���X�����̌��ʁi�M�����������ʁj�������܂��B

�����������x�X�g���X�����̌��ʂ������Ƃقړ����ł��邱�Ƃ�������܂���

NEWS�@���@�\����HighFunctionAlloy�J������V�����

- �@�@�@1966�N�`1997�N

-

"Ein Gonio- Mikroskop und einige Anwendungen" iMax Planck Institute in Germany�����f�ځB

*T.Taoka,K.Ogasa,E.Furubayashi,and S.Takeuchi,Jour.Inst.Met.30(1966)820/26

(in Japanese)

*�h�X�p�������ɂ�錋�����ʂ́h����h

�������ȑ呲�ƌ����_��1965�N�x�B

1966graduation thesis of Tokyo University of Science�B - �@�@�@2000�N

-

"Jewelry Manufacturing with the New High Carat Golds"by sub8.html �ւ̃����NBernardin,GOLD TECHNOLOGY,ISSUE No.30,WINTER 2000.

- �@�@�@2009�N7��

-

�c�[���G���W�j�A�i�Z�p��j�Ɍf�ځB�g���m����x���`���[�̒���

���n�[�h�f�B�X�N���C�L�^�}�́i�����x�L�^�A�N�����R�[�e�B���O���������j�̊J���E�����B

- �@ �@2007�N�`2009�N

- �@�@�@2009�N�Q���P��

- �@�@�@2009�N�`Present

-

�����������@�\����Fine Crystallite High Function Metal Alloy�̓����ƓK�p���i�B